Electric Vehicles - Are They The Best Option?

.png)

With the upcoming ban on sales of new petrol and diesel cars in the next eight years, electric and hybrid vehicles are becoming the machine of choice for drivers. With nearly 40 million vehicles being driven in the UK, and the cost of fuel skyrocketing as a result of rising fuel prices worldwide, opting for a more eco-friendly vehicle option seems the most logical choice.

What does this mean for manufacturing organisations?

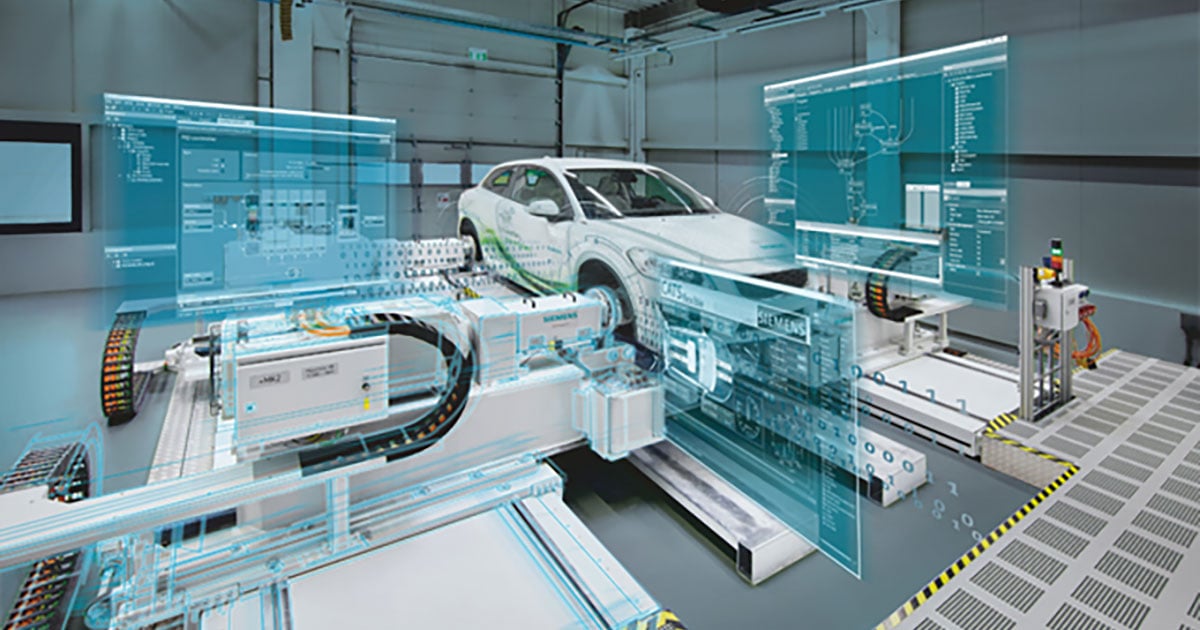

Simply put, the demand for hybrid and electric vehicles has increased and manufacturers are in a race against competitors to become the vehicle provider of choice. Electric vehicles were once a mere thought of the future but as technological advances change the game for manufacturers, consumers are more likely to shift towards more affordable options as the market for EVs widens and eco-friendly consciousness increases.

Electric vehicles of course need to be charged - and electric charging points are set to reach 300,000 in the UK - overtaking fuel stations. Executive Network Group is committed to positive change and has recently installed an additional 4 charging stations, bringing the total up to 6.

One of the biggest challenges for EV manufacturers is cutting down on uncommon and expensive metals in batteries that are also problematic due to the mining resulting in environmental and social costs. Different vehicles require varying amounts of metals – but on average a single car lithium-ion battery pack can contain approximately 8kg of lithium, 35kg of nickel, 20kg of manganese and 14kg of cobalt (Argonne National Laboratory). Since entering the market in the 1990s as small, portable batteries, lithium-ion batteries aren’t likely to be steered away from in the near future and are likely to continue to be the dominant option for a while due to decreasing costs and improved performance.

Not much in the modern world comes without an environmental cost, however, and the mining of metals necessary for EV batteries comes with its own ethical price. Current methods of metal extraction involve incredibly high levels of energy; although the increase of EV manufacturing will displace fossil-fuel extraction which comes with its own environmental costs.

Cobalt however, comes with its own challenges. It is the most valuable component of current EV batteries and more than 60% of global supply of cobalt is mined in the Democratic Republic of the Congo. Cobalt is toxic if it isn’t handled properly and with child labour and worker’s health being exposed to higher risk, human rights activists have raised concerns with cobalt mining.

Battery recycling presents further challenges to ensure that valuable metals in car potteries can be efficiently reused. If manufacturers are to make batteries without cobalt, the difficulty increases as many materials are cheaper to mine than they are to recycle, which has detrimental effects in terms of environmentalism.

Electric vehicles are certainly the cars of the future, but everything comes with a cost and its own challenges – will this change be at the detriment of future generations?

Further Reading

https://www.nature.com/articles/d41586-021-02222-1

.png)